Compressed Air Energy Storage: An Overview

Written by Amardeep Dhanju

February 10, 2026

What is Compressed Air Energy Storage (CAES)?

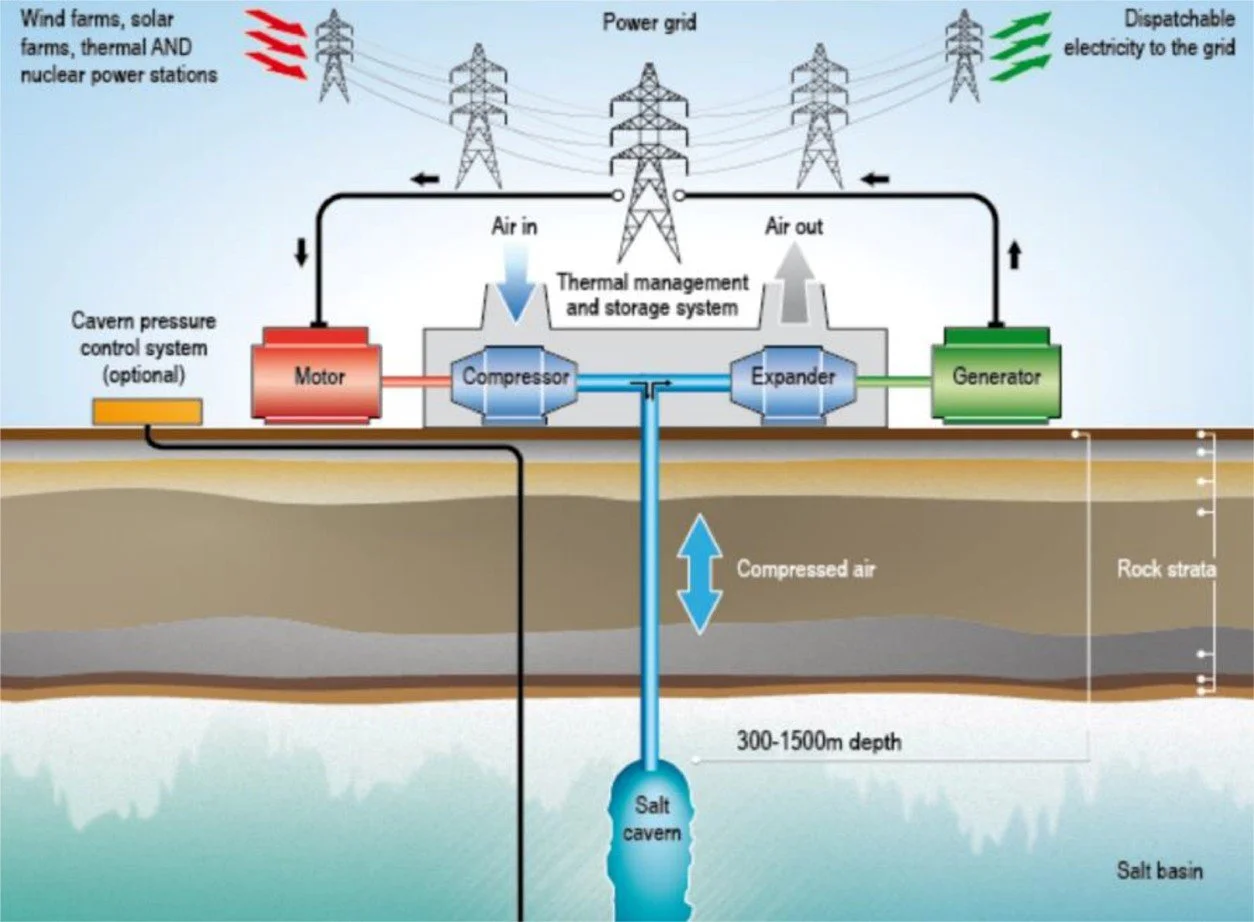

Compressed air energy storage (CAES) is a mechanical, long duration energy storage technology that stores energy by compressing air and injecting it into subterranean caverns. When electricity is needed, the stored air is released, expanded through a turbine, and converted back into electrical power.

CAES facilities typically can generate power ranging from 100-500 MW. This technology provides flexibility, allowing operators to control both the time of day and duration of discharge. Discharge periods can range from approximately 4 hours to more than 100 hours.

How do CAES Systems Work?

CAES systems operate in two phases – charging and discharging. During the charging phase, compressors draw in ambient air, compress it to high pressure (up to 70-100 bar)[1] and store it in a geologic formation. Charging (storage of compressed air) is generally carried out during periods of low electricity demand and high renewable energy generation. During periods of high electricity demand, the pressurized air is released from the storage cavern and expanded through turbines to drive a generator and produce electricity. This completes the storage cycle.

The main components of a CAES facility are the following:

Storage facility: A CAES facility needs access to a suitable geologic formation capable of holding large volumes of compressed air. Common options include underground salt caverns, depleted natural gas or oil reservoirs, and hard-rock caverns. At a smaller demonstration scale, above ground pressure vessels may be used to hold the compressed air.

Compression system: Multi-state compressors are used to reduce the amount of energy needed for the air to reach high pressure. Intercoolers are used to remove heat generated during compression. Important design considerations include compression efficiency, effective thermal management, and sufficient grid interconnection capacity to support power demand during charging operations.

Electricity generation system: Power is generated when stored compressed air is released from the storage cavern and directed through a high-pressure expander that drives turbines connected to generators. Two primary types of generation systems commonly deployed include diabatic and adiabatic systems. In a diabatic system, compressed air is combusted with fuel during expansion to heat it before it enters the turbine. An adiabatic system captures and stores the heat generated during compression in dedicated thermal energy storage systems and reuses it during air expansion (when compressed air is released from storage) for power generation. Recovering this thermal energy significantly improves system efficiency and can reduce or eliminate the need for supplemental fuel.

Connection to the electric grid: External power is required to compress the air, and power generated must be exported to the grid.

In addition to these core subsystems, CAES projects require extensive balance-of-plant infrastructure, including air handling and piping, pressure control and safety systems, monitoring and control software, grid interconnection facilities and substations, cooling systems, and backup or emergency venting. According to an EPRI report, a 100 MW plant usually occupies 1 acres of space above ground.

CAES projects are capital and infrastructure intensive since they require large upfront investments in specialized subsurface storage (e.g., caverns), compression and generation equipment, and extensive supporting infrastructure. Project development typically involves detailed geological surveys and drilling, environmental impact assessments (including air quality, noise, and subsurface impacts), securing land access and mineral rights, establishing interconnection agreements, and obtaining required local, state, and federal permits.

Operational characteristics of a CAES system (source: Olabi et al., 2021)

Benefits of CAES

The primary advantages of CAES system include:

The ability to provide long-duration energy storage, with discharge duration ranging from 10 hours to more than 100 hours, depending on the storage capacity. This makes CAES well suited to address extended lulls in renewable generation, such as multi-day periods of low wind or solar output. CAES projects can also complement short-duration battery storage, with batteries delivering fast response services and CAES systems providing sustained energy delivery.

Air compression at CAES facilities can be powered by surplus electricity from renewable energy sources. In 2024 alone, California curtailed more than 3.4 million megawatt hours (MWh) of wind and solar output, enough to power over 518,000 homes for a year. This otherwise unused electricity could be harnessed to compress air and store energy for use during periods when renewable resources are unavailable.

CAES systems are economically viable at scales of hundreds of megawatts, making them suitable for bulk energy shifting, peak shaving, and capacity services. A key advantage is its long asset life, typically 30-50 years, which is comparable to conventional generation and transmission infrastructure. The Huntorf CAES plant in Germany, the world’s first and longest-operating facility, has been in reliable operation since 1978.

Because there is no electrochemical aging with a CAES system, storage capacity and efficiency do not materially decline with cycling. This results in reduced replacement needs and reduced long-term operations and maintenance costs over the life of the assets.

CAES also offers the potential for low cost per kilowatt-hour of stored energy, particularly in regions with access to salt caverns and other suitable geologic formations. Energy capacity scales primarily with cavern size rather than expensive manufactured materials, making CAES especially attractive for long-duration storage applications where batteries can become cost prohibitive. In addition, CAES presents a significantly lower fire risk compared to electrochemical battery storage.

Depending on the system design, CAES can operate as a low-carbon or a zero-carbon electricity resource. Adiabatic CAES systems, in particular, require no fossil fuels during operation and can be charged entirely with excess renewable generation. CAES projects may also repurpose depleted natural gas reservoirs, enabling reuse of existing subsurface assets while supporting the broader energy transition.

Drawbacks and Technical Challenges

CAES faces some drawbacks and challenges.

Limited locations with suitable geology: One of the most significant drawbacks is its strong dependence on suitable geologic conditions, as many designs require specific subsurface conditions. These conditions are most commonly found in salt caverns, which are geographically limited. In addition, extensive site screening and subsurface characterization are required before development can proceed. This geologic dependency introduces additional complexity, cost, and development risk for CAES projects.

Lower generation efficiency: CAES systems generally exhibit lower round-trip efficiency - a measure of how much energy is obtained back from the storage system - than some other energy storage technologies, particularly lithium-ion batteries. While the lithium-ion battery systems typically achieve round-trip efficiencies of 85% to 90%, CAES systems achieve efficiency ranging from about 40% to 75%, depending on the system type.

High cost: CAES projects typically require substantial initial investment compared to battery storage projects, including cost for geological exploration and cavern development, compression and expansion equipment, and in the case of adiabatic systems, thermal energy storage.

New technology: CAES also has relatively limited history of commercial deployment, with only a small number of utility-scale facilities operating worldwide. Adiabatic CAES, in particular, remains an emerging technology at utility scale, which can contribute to higher perceived technology risk among financiers, utilities, and regulators.

Size and scale: Unlike battery storage, CAES systems are not modular and cannot be rapidly deployed or easily scaled in small increments. They are best suited for centralized, utility-scale applications located at a single site designed to serve the bulk power system, rather than distributed or fast-deployment use cases.

Examples of CAES Projects

Following are examples of CAES projects around the world:

The first utility-scale CAES storage project was the 290 MW Huntorf plant in Germany that opened in 1978 and uses a salt dome cavern as a storage medium. The project was later upgraded to 320 MW.

In the US, the first project was commissioned in 1991 in McIntosh in southwest Alabama. This 110 MW facility utilizes salt caverns located approximately 1,500 feet underground.

There are several projects in China, including what was previously the largest operational facility to date - a 350 MW plant in Shandong Province. This facility was recently surpassed by a 2.4 GWh, 600 MW project in Jiangsu province which became operational in January 2026.

In California, the Willow Rock Energy Storage Center is a 500 MW facility currently in late-stage development in Kern County. The project has a discharge capacity of 4,000 megawatt hours (MWh), enabling more than eight hours of continuous energy delivery at full output. Willow Rock is designed to store excess renewable generation, particularly solar energy that is frequently curtailed during afternoon hours and discharge it during periods of peak demand.

The facility will include an underground air storage cavern, four high-efficiency turbines, advanced thermal storage systems, and a 19-mile 230 kV transmission line. The project was approved by the California Energy Commission (CEC) in December 2025, with construction expected to begin in early 2026, supported by a $1.76 billion U.S. Department of Energy loan guarantee. The Willow Rock facility represents a significant step towards improving the reliability and availability of renewable energy when it is needed most.

Conclusion

CAES offers a promising pathway to enable long-duration, large-scale energy storage that would support the integration of utility-scale renewable resources into the grid. While challenges remain, technological advances are addressing many of these concerns by eliminating fuel combustion and improving system performance. The Willow Rock Energy Storage Center is expected to demonstrate how CAES can reduce renewable curtailment, enhance grid reliability, and support the transition to a low-carbon energy future.

[1] A pressure of 1 bar is approximately the average atmospheric pressure on Earth at sea level.